used club car rear seat kit

2. Variety of Options The best suppliers offer a range of options in terms of colors, finishes, and styles. This is important because your roofing choice should complement the overall design of your home or building. Suppliers who provide customizable solutions can help you achieve the desired look while maintaining functionality.

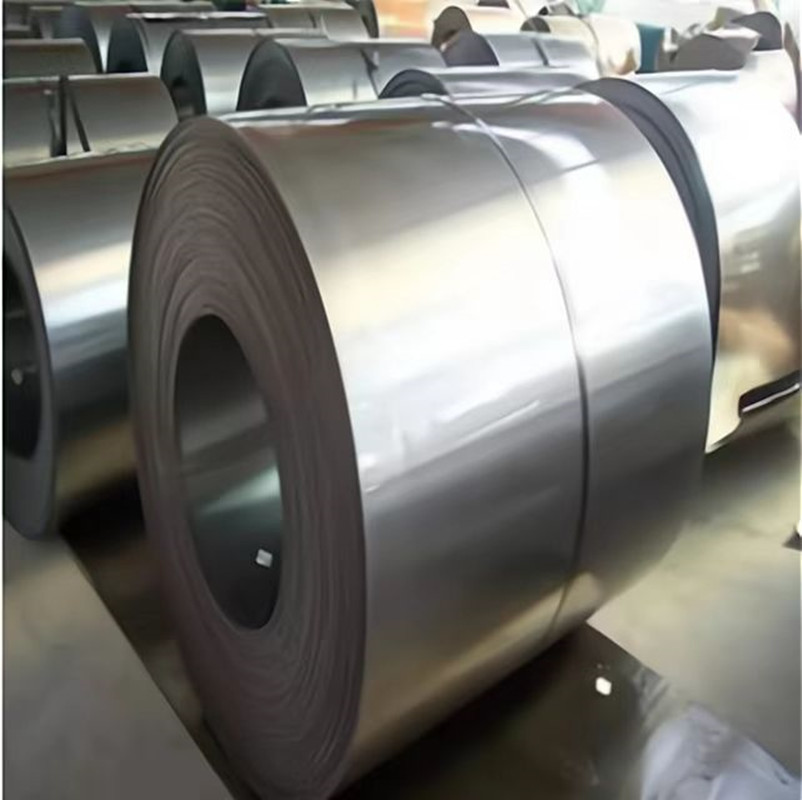

classic rib metal roofing supplier

One of the primary reasons for the growing preference for metal roofing is its exceptional durability. Unlike traditional roofing materials such as asphalt shingles or wood, metal roofs can withstand extreme weather conditions, including heavy rains, strong winds, and snow accumulation. This resilience translates into a longer lifespan, often lasting 40 to 70 years compared to 15 to 30 years for conventional roofs. With many modern metal roofing suppliers offering warranties of 30 years or more, property owners can have peace of mind knowing that their investment is well protected.

1. Surface Preparation The success of soldering hinges on proper surface preparation. Before soldering, it is essential to remove any oils, dirt, or oxidation from the surface. For galvanized iron, this often means using a wire brush or sandpaper to clean the area. It's also critical to remove the zinc coating at the joints to promote better adhesion.

soldering galvanized iron manufacturer

مزلقة تخفيض الضغط.

One of the most significant advantages of LNG is its lower environmental impact compared to traditional fossil fuels. When burned, LNG emits about 50% fewer carbon dioxide (CO2) emissions compared to coal and around 30% less than oil. Moreover, it produces virtually no sulfur dioxide (SO2) or particulate matter, which are significant contributors to air pollution and health problems. As countries grapple with climate change and strive for greener energy solutions, LNG presents itself as a cleaner bridge fuel that can support a transition towards more sustainable energy production.

الغاز الطبيعي المسال

صمام منظم ضغط الغاز. For instance, high-pressure regulators are used in industrial settings where large quantities of gas are required, while low-pressure regulators are more suited for residential or commercial use. Additionally, some regulators are designed for specific gases, such as natural gas, propane, or oxygen, to ensure compatibility and safety.